Raisin Types

-

Sultana Raisin Light Brown Special wholesale price + analysis + sale offer

Sultana Raisins Light Brown are dried Seedless grapes of the Vitis vinifera species. Customers also know this raisin as Malayer Raisin or Seedless Thompson. As it is clear from its name the color of this raisin is light brown. Farmers… -

sultana raisin dark brown special wholesale price + analysis + sale offer

This kind is prepared by drying the fruit in full sun and results in a dark color. -

Green Raisins ( Jumbo Raisins ) wholesale price + analysis + sale offer

Green Raisins | Jumbo Raisins : Green Raisins also are known as Green Jumbo Raisin, Kashmari (Kashmiri) Green Raisins and Green Long Raisins. As it is clear from its name the color of this raisin is green. Raisins, in general,… -

Golden Raisin Special wholesale price + analysis + sale offer

This kind is oven-dried and then sulfur is added to preserve its color. -

Golden Long Raisin

Golden Long Raisin also is known as Golden Raisin Jumbo or Kashmari Golden Raisin. As it is clear from its name the color of this raisin is golden. Raisins, in general, are dried grapes.

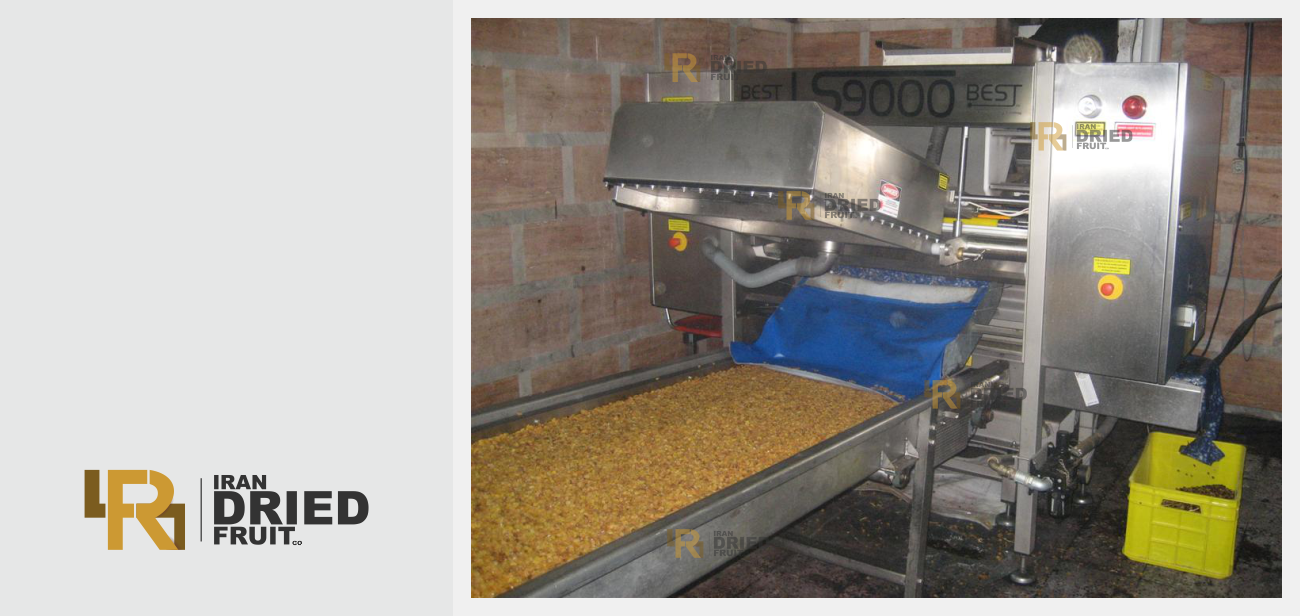

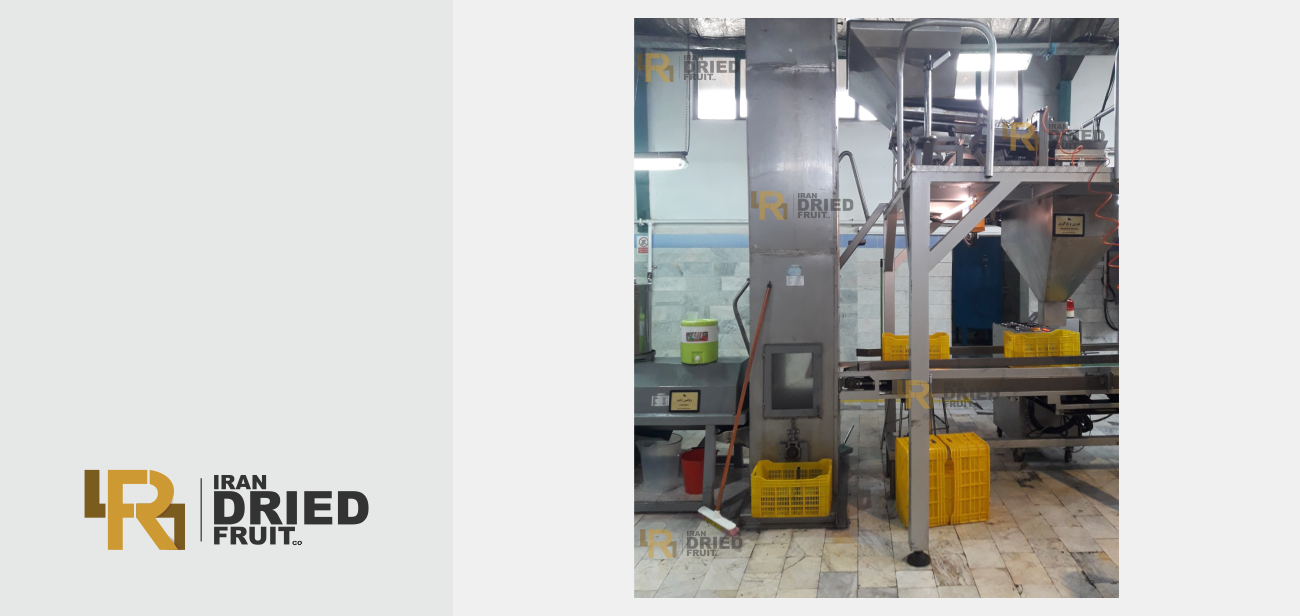

Raisin Factory

At the center of the Iranian raisin production province, we have implemented our Manufacturing factory with a wide variety of technology and different types of machinery ranging from laser Sort machine, Metal Detector, X-Ray Scanner, hair-burner, etc.

We also have a wide range of Quality Control equipment to carry out precise control on the quality of our products in all the production stages; from farm to the warehouse and after that transportation and loading.

The history of raisin The raisin was discovered accidentally, many years before Christ. People ate grapes but did not know that if they were to dry the grape, it would become this useful and delicious dried fruit called the raisin. Historians claim that the Phoenicians and Armenians were the first nations to produce raisins. Phoenicians established vineyards in Spain and Greece that were fitting for cultivating raisins and the Armenians established their vineyards in Iran, Turkey and Iraq. The Greeks and Romans had a high demand for raisins and then other countries started to use raisins as well.

Uses of Raisin

Customers mostly use Raisin for below items:

- Cakes and Bakeries

- Sweets and Confectioneries

- Jams, Syrups and Compote

- Snacks

- Mixes Nuts and Dried Fruits

Raisin Packing:

Some pictures of different types of packing : 10 kg Cartons (Regular Packing)

Botanical Information of Raisins

The grape is from the vitaceae family and has more than 800 varieties. The most common variety of grape is the vinifera. Grapes can be different colors, such as green, red, purple and yellow. Grapes can be eaten plain or processed into raisins, fruit juice and marmalade.

Nutritional Value of Raisins

100 grams of raisins contains about 300 calories and is composed of approximately 75% carbohydrates, 5.3% fiber, 2.8% protein, 0-4% fat and is rich in potassium

| Principle | Nutrient Value | Percentage of RDA |

|---|---|---|

| Energy | 74Kal ( 3.9 Kj) | 4% |

| Carbohydrate | 19.18g | 15% |

| Protein | 0.75g | 1.5% |

| Total Fat | 0.30g | 1% |

| Cholestrol | 0mg | 0% |

| Dietary Fiber | 2.9g | 7% |

Vitamins

| Principle | Nutrient Value | Percentage of RDA |

|---|---|---|

| Folates | 6μg | 1.5% |

| Niacin | 0.400 mg | 2.5% |

| Pantothenic acid | 0.300 mg | 6% |

| Pyridoxine | 0.113 mg | 9% |

| Riboflavin | 0.050 mg | 4% |

| Thiamin | 0.060 mg | 5% |

| Vitamin A | 142 IU | 5% |

| Vitamin C | 2 mg | 3% |

| Vitamin E | 0.11 mg | 1% |

| Vitamin K | 4.7 μg | 4% |

Electrolytes

| Principle | Nutrient Value | Percentage of RDA |

|---|---|---|

| Sodium | 11% | 1 mg |

| Potassium | 749 mg | 16% |

Minerals

| Principle | Nutrient Value | Percentage of RDA |

|---|---|---|

| Calcium | 50 mg | 5% |

| Copper | 0.318 mg | 35% |

| Iron | 1.88 mg | 23% |

| Magnesium | 7 mg | 2% |

| Manganese | 0.299 mg | 12% |

| Phosphorus | 101 mg | 15% |

| Selenium | 0.6 µg | 1% |

| Zinc | 0.22 mg | 2% |

phyto-nuteints

| Principle | Nutrient Value | Percentage of RDA |

|---|---|---|

| Carotene-α | 0 µg | -- |

| Carotene-ß | 85 µg | -- |

| Crypto-xanthin-ß | 0 µg | -- |

| Lutein-zeaxanthin | 9 µg | -- |

Global Trade Statics of Raisins

The statistics of Iranian raisin exports, according to the Customs Organization of Iran, are shown below (values are in millions of dollars):

Note: Statistics are from March of each year.

According to FAO statistics (2003), Iran is the second largest exporter of dried figs in recent years and Iranian dried figs are exported to many countries.

3 kind raisin

3 kind raisin